Today’s golf clubs are the result of many years of evolution. Over those years golf club materials have changed and new golf club design and manufacturing techniques have been developed and refined. Shafts have evolved from wood to steel to graphite.

Today’s golf clubs are the result of many years of evolution. Over those years golf club materials have changed and new golf club design and manufacturing techniques have been developed and refined. Shafts have evolved from wood to steel to graphite.

Driving clubs and fairway “woods” have changed dramatically over time but particularly in the last 20 years. Titanium has revolutionized the drivers look and effect on our games and a variation on the wood design called a hybrid club is causing a sensation throughout golf. Irons too have changed dramatically, mostly during the 1980s, as Ping pioneered perimeter weighting and the cavity back design.

Ping’s perimeter weighted designs has been refined by Callaway and Taylor Made and the area of “game improvement” irons is clearly in it’s “hay day”.

Putters too have become high tech and now scientific testing is used to advance their design and capabilities. You could argue that golf clubs have changed more in the last 20 years than in the last 200.

Has all this technology changed our games?

What has all these changes meant to our games. The USGA has said that the average handicap has changed little in the last 30 years. Apparently all this technology hasn’t helped us play better. After all, is it the archer or the arrow that hits the target. Clearly it’s the archer’s job—BUT, perhaps the archer has not taken advantage of what the new arrows can do.

This debate could go on, but it is true that many of us average golfers know little about the golf club and how it effects our game. The fact is, few of us are playing with clubs that are fit correctly for OUR games. Understanding golf clubs better and how they work, can only help us. Let’s start by learning a little about the design of golf clubs.

The Parts of a Clubhead

All golf club heads have basically three parts; the hosel, the face and the body. Irons, putters, wedges and wood style clubs may look completely different but they all share those three parts.

The clubhead is further divided into the toe, the heel, and the sole. The design of each can effect how the club performs particularly in the case of irons. Today’s iron designs have further refined the cavity behind the face and the top edge or top line. All play a part in the performance of a club.

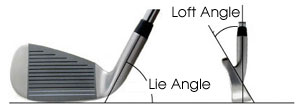

Other key details of a golf club include the loft and the lie. The loft determines at what angle the ball comes off the club face and therefore the distance the ball travels. The lie determines how that face sits on the ground for a given golfer. Each is very important to club performance. More loft to a club means the ball travels higher and shorter for a given swing speed. The lie can determine wether the ball has a tendency to go straight, left or right. We’ll talk more about the effects of lie and loft in our club fitting section.

The variation in loft from club to club should be uniform so that the difference between each club’s distance is about 10-15 yards. What can be confusing is that each manufactuer may have a different standard loft for a particular iron. One company’s 7 iron may be 40 degrees and anothers’ 37. In fact, loft can vary from club model to club model within the same company.

There’s a gap in your wedges!

Manufacturers have been making their clubs with less loft to create the illusion that we are hitting them farther. The only club that didn’t change was the sand wedge because the standard 54-56 degrees of loft was required for chipping and sand play. That meant there was a big GAP between the sand wedge and the pitching wedge’s lofts. To fill that void the GAP or ATTACK wedge was created. The gap wedge has a loft between the pitching and sand wedge. Aaah those tricky manufacturers.

Another interesting fact is that the 7 iron of 30-40 years ago probably had 4-5 more degrees of loft than today’s 7 iron. And you thought you were just getting stronger over the years didn’t you.

Where Are The Manufacturers?

Speaking of manufacturers, where do golf clubs get manufactured? This is something that has changed dramatically in the last 20 years. TaylorMade, Callaway, Ping, and Nike, etc. are considered by the public to be the Original Equipment Manufacturers or OEMs. But do they actually do the manufacturing? Not exactly.

Ping is the only one that actually owns it’s own foundry for manufacturing irons (they too outsource their wood production). All the others outsource their actual manufacturing to foundries in China. In fact, there are only about a dozen foundries that produce the majority of the quality clubs in the entire world. Why! It comes down to cost. The Chinese just do it cheaper and better than anyone else. Sounds like a familiar story.

So what do the OEMs do? They do the research and development that determines how the clubs will be manufactured. The golf club designs still come from the OEMs but those designs are manufactured in China. They still do all the marketing. And oh yes…they still pay all the pros to play their clubs. More on that later.

Iron Manufacturing and Materials

Once the golf club design is completed, the two ways to manufacture irons are investment casting and forging. The casting process involves pouring molten metal into preformed casts or molds. All cast clubs are made from stainless steel. Stainless steel combines iron with nickel and chromium and other trace materials. Most good quality cast irons are made from either 17-4 or 431 grade stainless steel. Cast clubheads made from 17-4 steel are a little harder than clubs made from 431. If you want to have the lie and loft of your clubs adjusted it will be a little bit more difficult with 17-4 steel. Not impossible but more difficult. A good clubmaker with the right tools should still be able to handle the job.

By the way, if you find irons made from zinc, they cannot be altered at all. Zinc ironheads are the cheapest ironheads and are typically offered by mass merchandizers. You can identify them by their large hosels and their softness which means they will ding and get marked up easily. Stay away from these clubs if you are looking for quality clubs.

It’s no coincidence that the manufacturing process for most cavity back irons has been casting. The investment casting process produces clubs from molds that can be formed in very intricate shapes. These shapes allow for variations in weight distribution in the clubhead also known as perimeter weighting. The casting process is also relatively inexpensive compared to the alternative which is called forging. Forging uses massive machines that hammer the raw metal into the desired shape. It’s more expensive and more limited in terms of variations in club design. It does create a club with a very soft feel and better players believe they can control and “work” the ball better with forged clubs.

The steel used for forged clubs is carbon steel. This is the material that has been used for quality clubs since the 1800s. Carbon steel is made from good old fashioned iron (Fe) combined with carbon. Carbon steel has a tendency to rust so it is usually electroplated (coated) with chromium and nickel. The advantage of carbon steel is that it is very malleable (soft) and so lends itself to the forging process. Some say hitting a ball with forged clubs has a softer feel. This softness does make it easier to adjust for lie and loft but it may also lead to the lie and loft changing over time due to use. This is why most pros have their lofts and lies checked often.

Driver Materials and Manufacturing

Drivers and fairway woods are manufactured using the same manufacturing processes as irons. Casting once again being the dominant process due to its flexibility and cost.

Most of today’s drivers and some irons are made from mutliple pieces welded together. Welding quality is something to look for in a good club. Unfortunately the welds are often inside the clubhead so you won’t be able to see them. Still, something to be aware of.

Typically driver faces are made from titanium and fairway woods and hybrid faces are made from steel. The top or crown is often made from a lightweight carbon fiber material. This lets the majority of weight be distributed lower and farther back in the clubhead. This lowers the center of gravity (CG) and the advantage is higher ball flight and more distance.

To learn more about how design effects the playability of each club type click on the link for each club type below.